Identify Product Manufacturability Issues and Cost Drivers Early in the Design Lifecycle

As a design engineer, you have a lot on your plate. The design you sent off two weeks ago has just landed back on your desk with a handful of edits from your cost engineer to improve manufacturability and cost. Now this redesign is your priority despite the fact that you’ve already moved on to another project. Ever-changing product requirements, design rework, shrinking deadlines, and late discovery of design issues stalling manufacturing are just some of the things that have you reaching for another BIG cup of coffee.

Do you ever wish design for cost and manufacturability was easier?

Now it is.

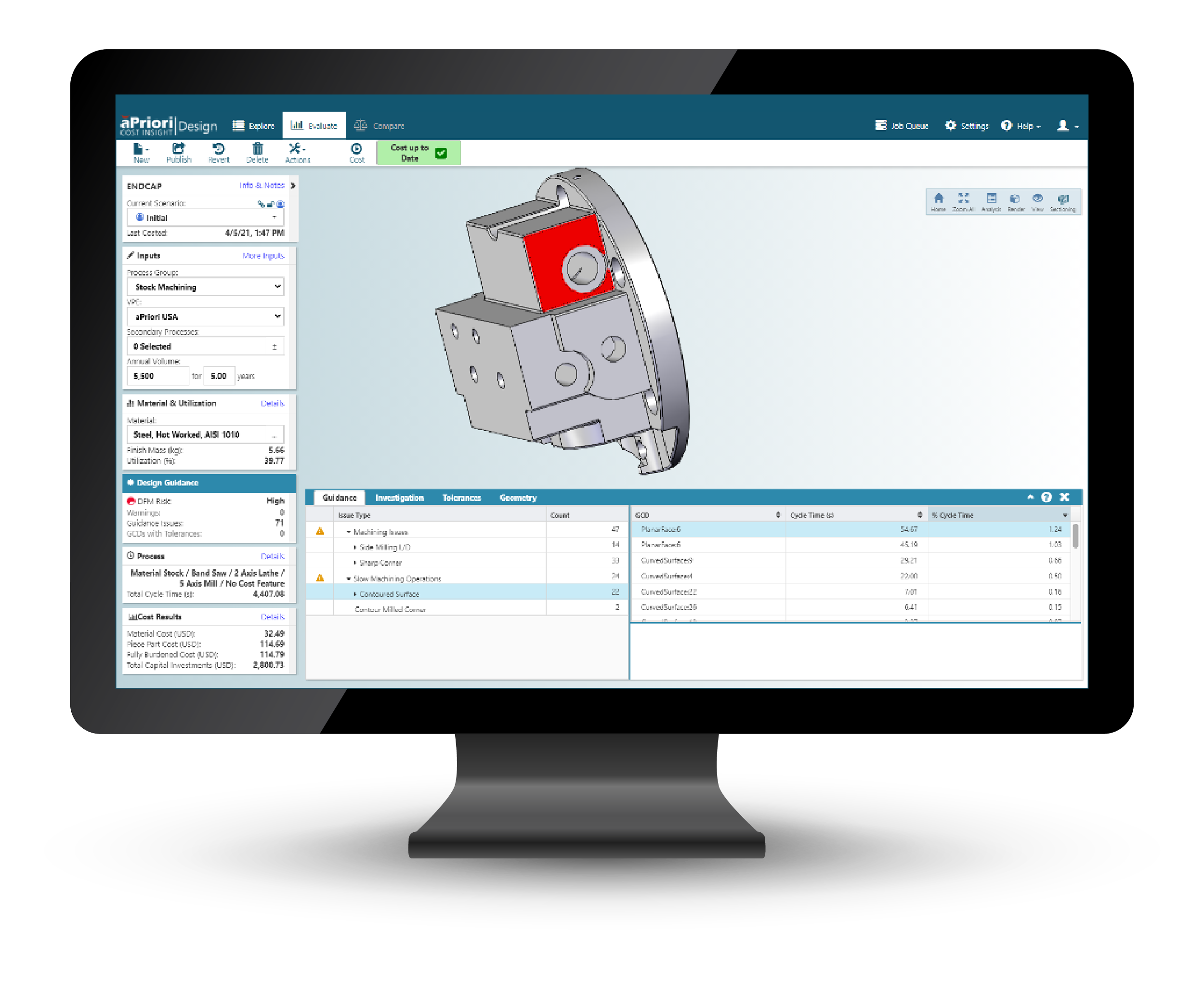

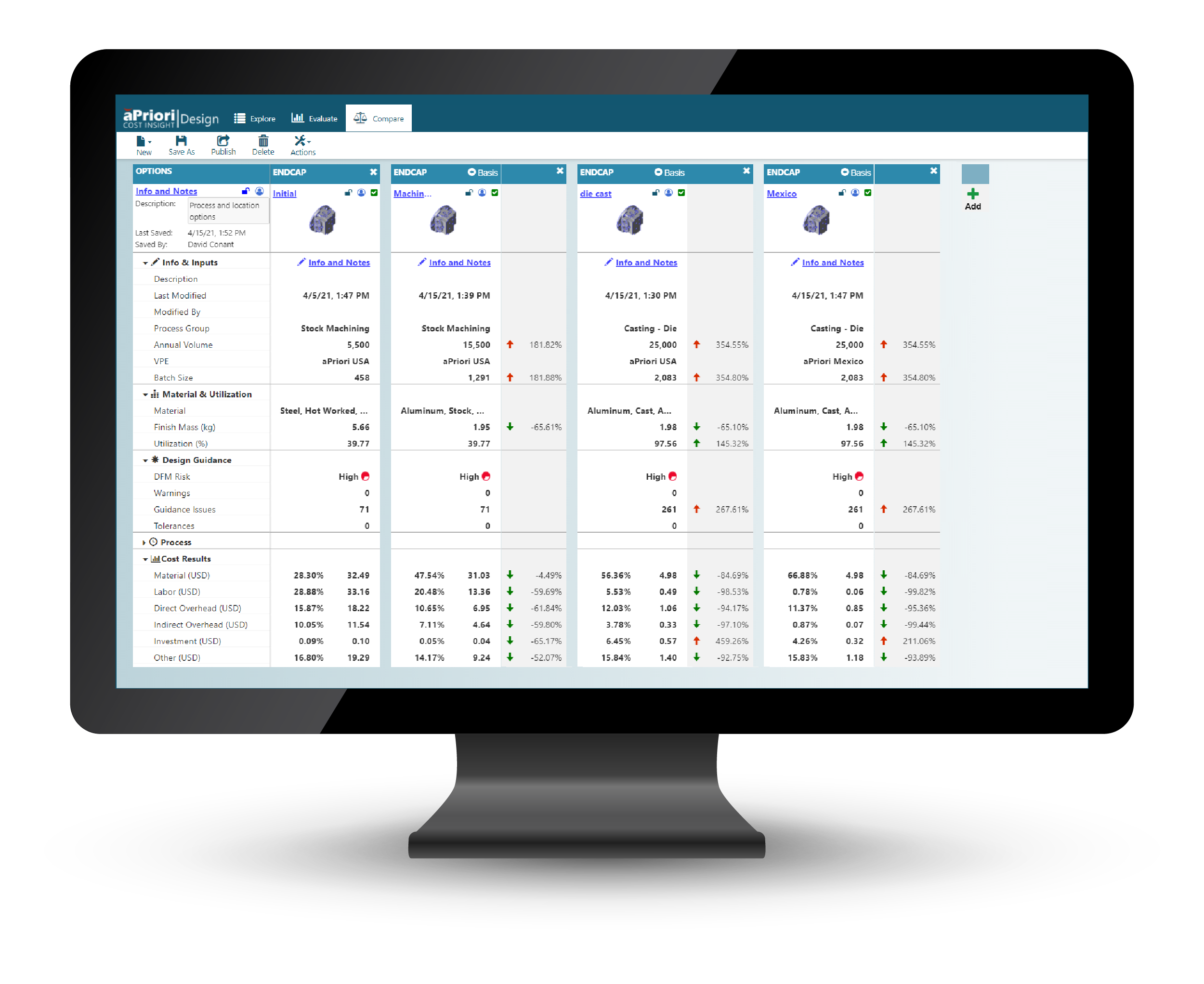

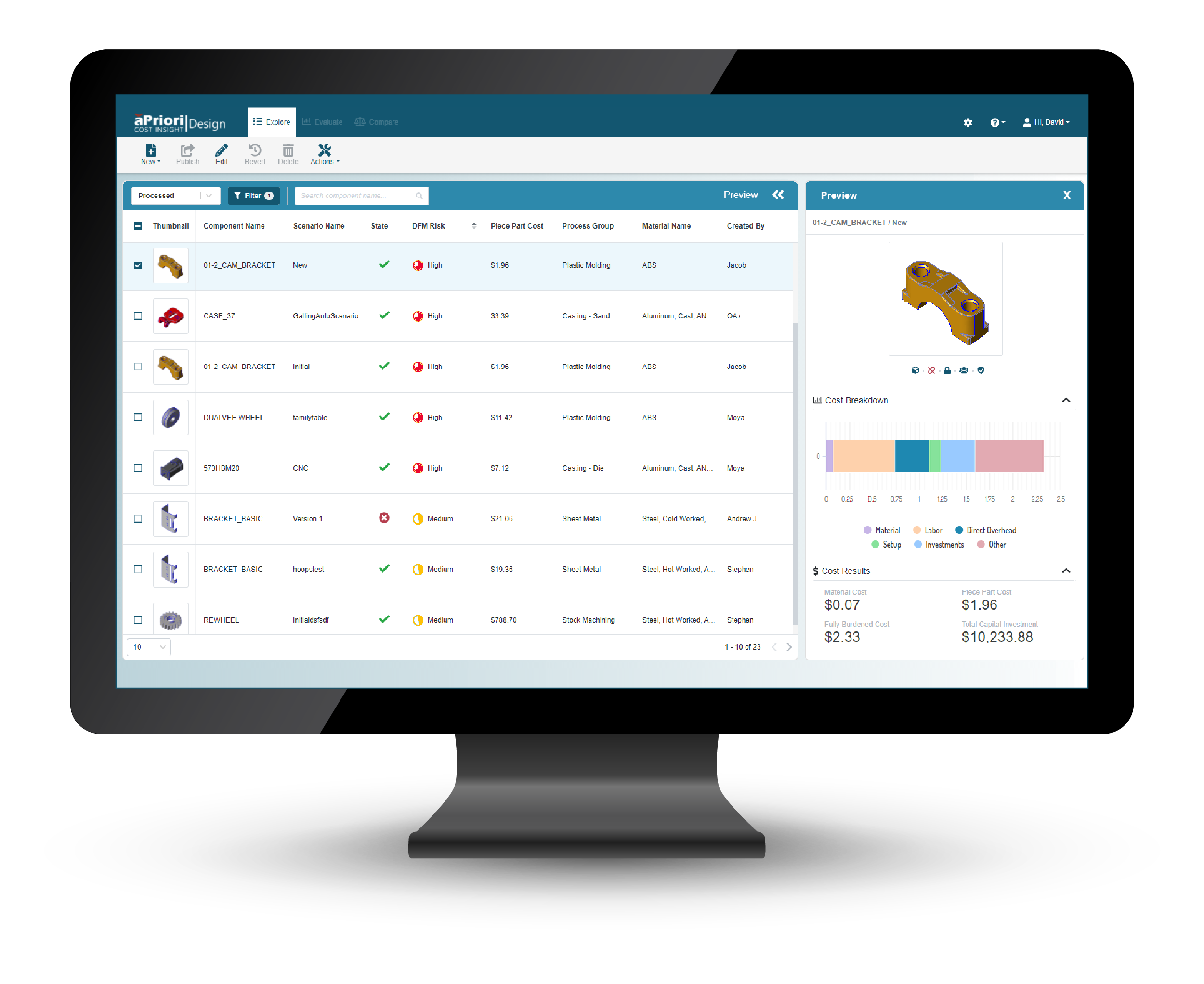

aPriori solves for the entire design engineering team by enabling you to manage the manufacturability of multiple projects simultaneously. In just seconds, you can identify and mitigate product cost drivers and highlight manufacturability issues before designs are released. Need real-time DFM and DTC guidance while you’re designing in CAD? We’ve got that covered too. aPriori offers multiple modes to deliver actionable insights so you can make smarter design decisions in less time.

Here's how it works:

Seeing is Believing. Request a Demo.

We’ll show you exactly how aPriori works.aPriori Solutions for Design Engineering

Connect aPriori to your PLM system for automated manufacturing simulation upon check-in of new or modified CAD designs.

Run thousands of CAD designs through aPriori to generate a detailed comparison of should cost vs your estimate. Quickly and easily identify outliers that offer potential for re-negotiation, re-bid or re-design.

Detailed reports of cost data for your products. Create custom dashboards to consistently monitor new product initiatives against design to cost targets.

Collaborate with other departments and align your design for manufacturability goals with the entire product lifecycle team. From project managers to design engineers to sourcing and supply chain professionals.