This article will help you to understand how design for manufacturability can support the acceleration of new product pipelines to drive the revenue generation engine at your business. It will also help you to build resilience to withstand future epidemics by being part of the digital transformation of your engineering team.

The world of product development has changed dramatically in 2020. Thousands of manufacturers across all verticals are re-aligning their 2020 product plans. Ramping back up to full productivity will require new ideas and new techniques.

One such technique is design for manufacturability (DFM). DFM is the engineering practice of designing products to optimize their manufacturing ease and cost given form, fit, and function requirements. Tying manufacturability issues directly to design decisions will reduce product costs and development time.

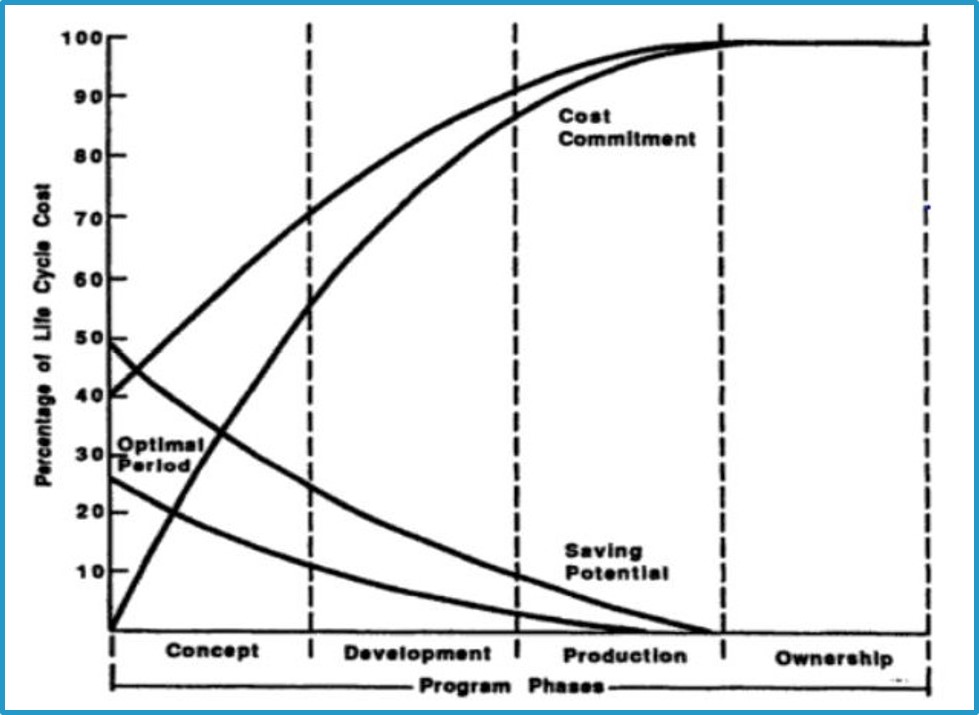

The main goal of designing for manufacturability is to design streamlined products that allow reduced and optimized manufacturing cost during the design phase when cost-saving opportunities are greatest (see image 1). It also helps to avoid situations where the engineering team designs products without considering how they should be manufactured and sends designs to manufacturing and/or sourcing that can’t be worked with.

DFM will aid manufacturers in reacting to the current crisis, creating a successful plan for recovery, and reimagining new product introduction techniques going forward.

What is DFM Software?

In a world where most manufacturing has been outsourced to suppliers in remote destinations across the world, an understanding of how products are produced has diminished significantly. This is especially prevalent in younger engineers who recently graduated from university. They create designs that may be functional and aesthetically pleasing but are either impossible, very difficult, or overly expensive to manufacture.

Design for Manufacturability software replicates real-world manufacturing environment conditions, including raw materials available, labor time and costs, tooling costs, available machinery and process routings, machine cycle times, overhead costs, and much more. This software typically uses a 3D CAD model as a primary input along with a few additional pieces of information input by the operator, such as production volume, location of manufacture, and primary manufacturing process to be used. The system then simulates all the actual manufacturing operation combinations available in that factory to identify the most optimal approach.

The outputs of a modern DFM system typically include some type of graphical feedback to the operator in the form of heat maps on the CAD model design. It will identify all of the individual features that are potential problems in the factory that have been selected. Highly advanced DFM software will even provide manufacturability guidance that instructs the operator how to eliminate the problem, typically by making small changes in the CAD model. For example, change the tolerance of a drilled hole to allow for a single-tool material removal operation instead of requiring 2 or 3 different tools.

How Does DFM Contribute to Reduced Costs and Development Time?

- Compare design alternatives to understand which has the least manufacturability issues and is least expensive to produce.

- Identify unnecessary design features that impact requirements for additional manufacturing operations.

- Uncover why a design is resulting in higher bids than expected from supply chain partners.

- Ensure that manufacturing issues don’t turn up in later stages of the design life cycle and hold up a time-sensitive product rollout.

How the Right DFM Tool Can Aid in Reducing Product Development Time

Understanding how each component design affects overall manufacturing needs requires the right tools. DFM software is capable of simulating dozens of different manufacturing processes based on design-level inputs like 3D CAD files. While employing the techniques mentioned above, the right tools are the key to unlocking the analytical problem at the heart of DFM.

In order to get the right products to market on time and on budget, design engineers need the right tools that can help them judge the manufacturability, efficiency, and manufacturing cost of their designs in a consistent way.

Without those tools, design engineers either stay within areas of expertise (where they feel confident to make the right decisions) or they consult with process and manufacturing subject matter experts (which is time-consuming).

To harvest the full potential of DFM effectively, design engineers need the tools to consistently evaluate the manufacturability and cost of different design alternatives against each other in a timely manner.

Speed Up Product Development by Evaluating Manufacturability and Cost Simultaneously

Using DFM software that works directly with your CAD model, design engineers access their design and input some basic information about the part or assembly (i.e. annual volume, location, material). The software then analyzes the CAD geometry for its cost drivers within a given manufacturing process group. Within this process group, the software then evaluates which routings are suitable to manufacture the part and what the cycle time and material utilization should be.

The entire process happens almost in real-time. Due to the minimized manual inputs, it delivers consistent results allowing engineers to explore ideas that may not be common for them today.

Summary

Designing for manufacturability utilizing DFM software helps companies design products that are easier to manufacture, which results in lower manufacturing cost.

To fully experience DFM, companies need to provide the tools that support their design engineers with manufacturing and cost information throughout product development.

To dig deeper into the DFM methodology, download our guide: A Practical Guide to Design for Manufacturability. This guide defines DFM, looks at its importance for manufacturing organizations, outlines some fundamental principles, and concludes with a look at some real examples of design for manufacturability in action.

A Practical Guide to Design for Manufacturability

Learn how design choices impact the production process, including impact on cost.